Scaling out Factor VIII production efficiently is a critical challenge in biotechnology, demanding innovative solutions to meet growing demands. This discussion delves into how the process model for concurrency, particularly Factor VIII (VIII), can revolutionize production workflows. We will explore the fundamental principles of scaling out, the intricacies of Factor VIII manufacturing, and how concurrency strategies can alleviate bottlenecks, optimize resource utilization, and ultimately enhance production capacity.

The journey encompasses a detailed examination of the process model’s core components, implementation strategies, and the essential aspects of resource management within a concurrent system. From designing scalable workflows to implementing inter-process communication and monitoring performance, we will unravel the technical intricacies and offer practical insights. Furthermore, we will investigate real-world examples, case studies, and the measurable impact of these strategies, ensuring a comprehensive understanding of this transformative approach.

Introduction to Scaling Out with the Process Model for Concurrency (Factor VIII)

Scaling out in the context of Factor VIII processing involves distributing computational tasks across multiple processing units to handle increasing workloads and improve performance. This approach is crucial for meeting the demands of complex Factor VIII production, which requires efficient processing of large datasets and the execution of numerous concurrent operations. The process model for concurrency offers a robust framework for achieving this scalability.

Fundamental Concept of Scaling Out in Factor VIII Processing

Scaling out in Factor VIII processing is about expanding the processing capacity horizontally. This means adding more processing units (e.g., servers, virtual machines, or processing cores) to the system rather than increasing the capacity of a single unit. This is particularly important in Factor VIII production, where large volumes of data must be processed for tasks such as protein purification, quality control, and data analysis.

The goal is to maintain optimal performance even as the volume of data and the complexity of processing increase. This approach ensures that the system can handle peak loads and adapt to evolving requirements without significant downtime or performance degradation.

Overview of the Process Model and its Relevance to Concurrency

The process model, in the context of concurrency, allows a program to execute multiple tasks simultaneously. Each task runs within its own independent process, which can be distributed across multiple processing units. This is in contrast to a single-threaded approach, where tasks are executed sequentially. This model facilitates parallel processing, improving overall efficiency and throughput.Here’s how the process model works:

- Process Creation: The system creates independent processes, each with its own memory space and resources.

- Task Assignment: Tasks are assigned to different processes, allowing them to execute concurrently.

- Inter-Process Communication (IPC): Processes communicate and share data through mechanisms like pipes, message queues, or shared memory.

- Synchronization: Synchronization mechanisms (e.g., mutexes, semaphores) are used to coordinate access to shared resources and prevent data corruption.

This model is particularly relevant to Factor VIII processing because it allows for the parallel execution of various stages of production, from initial cell culture to final product formulation.

Benefits of Using the Process Model for Factor VIII Scalability

Employing the process model for Factor VIII scalability offers several key advantages, particularly in optimizing resource utilization and enhancing overall processing efficiency.The benefits include:

- Improved Resource Utilization: By distributing tasks across multiple processes, the process model ensures that all available processing resources are utilized effectively. This is crucial for maximizing throughput in Factor VIII production, where time is of the essence. For example, if one process is waiting for data from a specific step, another process can continue working on other steps without delay, preventing bottlenecks.

- Enhanced Performance: Parallel processing significantly reduces the overall execution time. By breaking down complex tasks into smaller, independent processes that can run concurrently, the process model accelerates the entire production workflow. Consider a scenario where multiple purification columns are used in Factor VIII production. The process model allows each column’s output to be processed simultaneously, leading to faster overall purification.

- Increased Reliability: The process model enhances system reliability. If one process fails, it does not necessarily bring down the entire system. Other processes can continue to operate, minimizing downtime and ensuring continuous production. For example, if a data analysis process crashes, the purification and formulation processes can continue uninterrupted.

- Scalability: The process model provides a natural framework for scaling out. As the demand for Factor VIII production increases, more processes can be created and distributed across additional processing units without significant code changes. This allows the system to adapt to growing workloads.

Understanding Factor VIII Production and Bottlenecks

Factor VIII (FVIII) production is a complex, multi-stage process. This process involves various stages, from cell culture to purification and formulation. Each step plays a crucial role in ensuring the final product’s safety, efficacy, and yield. Understanding these stages and the bottlenecks that can impede scalability is critical for optimizing production and meeting the growing demand for FVIII therapies.

Typical Steps in Factor VIII Production

FVIII production typically involves several key steps. These steps are carefully controlled to ensure product quality and consistency.

- Cell Culture and Expansion: This initial stage involves culturing genetically engineered cells (often Chinese Hamster Ovary (CHO) cells) that are designed to produce FVIII. The cells are expanded in bioreactors, providing a controlled environment for growth and FVIII expression.

- Harvesting: Once the cell culture reaches the desired cell density, the cells are harvested, and the cell culture supernatant (containing FVIII) is collected.

- Primary Purification: The harvested supernatant undergoes initial purification steps, which may include filtration, centrifugation, and chromatography. These steps aim to remove cellular debris and other impurities.

- Chromatography: Chromatography techniques, such as affinity chromatography, are employed to selectively capture FVIII from the partially purified mixture. This step is critical for separating FVIII from other proteins.

- Viral Inactivation/Removal: To ensure product safety, steps are taken to inactivate or remove potential viruses. These steps may include solvent/detergent treatment or nanofiltration.

- Further Purification: Additional chromatography steps or other purification techniques may be used to further refine the FVIII product and remove any remaining impurities.

- Formulation and Fill/Finish: The purified FVIII is formulated with stabilizers and excipients to maintain its stability and activity. The final product is then sterile-filtered and filled into vials or syringes.

- Quality Control: Throughout the entire process, rigorous quality control tests are performed to ensure the product meets the required specifications for purity, potency, and safety.

Common Bottlenecks that Limit Scalability in Factor VIII Manufacturing

Several bottlenecks can limit the scalability of FVIII manufacturing, hindering the ability to produce larger quantities of the drug to meet growing demand. Addressing these bottlenecks is crucial for improving production efficiency.

- Cell Culture Capacity: The capacity of bioreactors and the availability of cell culture media can limit the amount of FVIII that can be produced. Increasing the size or number of bioreactors can address this, but it requires significant investment and planning.

- Chromatography Resin Capacity: Chromatography is a critical purification step, and the capacity of chromatography resins can be a limiting factor. The amount of resin available, the flow rates, and the binding capacity of the resin can all affect the scalability of this step.

- Purification Process Time: Some purification steps, particularly chromatography, can be time-consuming. The duration of these steps can limit the overall production throughput.

- Viral Inactivation/Removal Step Efficiency: The effectiveness and efficiency of the viral inactivation/removal steps are crucial for product safety. Inefficient steps can slow down the process and impact the overall yield.

- Fill/Finish Capacity: The capacity of the fill/finish operations, which involves filling vials or syringes with the final product, can also be a bottleneck. The number of filling lines and the speed of the filling process can limit the production output.

- Quality Control Testing Time: The time required for quality control testing can also contribute to bottlenecks. The number of tests required, the complexity of the assays, and the availability of testing equipment can all impact the overall production timeline.

How Concurrency Can Help Alleviate These Bottlenecks

Concurrency, or the ability to perform multiple tasks simultaneously, can help alleviate many of the bottlenecks described above, improving the efficiency and scalability of FVIII manufacturing.

- Parallel Processing: Implementing parallel processing can allow multiple batches of FVIII to be processed simultaneously, increasing overall throughput. For example, multiple bioreactors can be operated in parallel, and multiple chromatography columns can be run concurrently.

- Optimized Workflow: By optimizing the workflow and streamlining the process, concurrency can reduce the time required for each step. This might involve using automated systems, optimizing chromatography protocols, and implementing real-time process monitoring.

- Resource Optimization: Concurrency can help optimize the use of resources, such as equipment and personnel. For example, multiple purification steps can be performed concurrently, minimizing the time equipment is idle.

- Enhanced Flexibility: Concurrency can enhance the flexibility of the manufacturing process. It allows for easier adaptation to changes in demand or unexpected disruptions. For instance, if one bioreactor fails, the other parallel bioreactors can continue production.

- Improved Throughput: By enabling multiple tasks to be performed simultaneously, concurrency can significantly improve the overall throughput of the manufacturing process, allowing for the production of larger quantities of FVIII.

The Process Model

The process model is a fundamental concept in concurrent programming, offering a structured approach to managing and coordinating multiple tasks that can execute simultaneously. It provides a framework for breaking down complex problems into smaller, independent units of work (processes) that can be executed concurrently, thereby leveraging the capabilities of multi-core processors or distributed systems to improve performance and responsiveness.

Core Principles of the Process Model

The process model is built upon several key principles that govern how processes are created, managed, and synchronized. Understanding these principles is crucial for designing and implementing efficient concurrent systems.

- Independence: Processes are designed to be largely independent of each other. Each process has its own memory space, resources, and execution context. This isolation minimizes the risk of interference and simplifies debugging.

- Concurrency: Processes can execute concurrently, meaning they can run at the same time, either on different processor cores or through time-slicing on a single core. This is the core feature that enables parallelism and improved performance.

- Communication: Processes often need to communicate and share data to coordinate their activities. This is typically achieved through mechanisms like message passing (sending and receiving messages) or shared memory (accessing a common memory region).

- Synchronization: When processes share resources or need to coordinate their execution, synchronization mechanisms are essential to prevent race conditions and ensure data consistency. Common synchronization techniques include mutexes, semaphores, and condition variables.

- Fault Tolerance: The process model can be designed to handle failures gracefully. If one process fails, it shouldn’t necessarily bring down the entire system. Mechanisms like process monitoring and restart can improve the overall reliability.

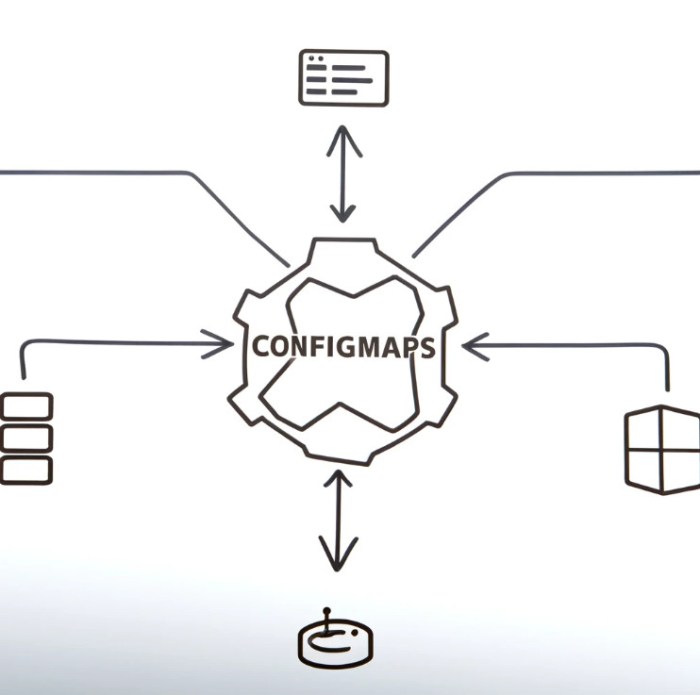

Basic Process Model for Factor VIII Production

Designing a process model for Factor VIII production involves breaking down the overall process into distinct stages, each handled by a separate process or set of processes. This allows for parallel execution of different production steps, potentially increasing throughput.

Here’s a basic model Artikel:

- Cell Culture Process: Responsible for growing the cells that produce Factor VIII. This process manages cell growth, nutrient supply, and waste removal. It is crucial for producing the raw material.

- Production Process: Takes the output from the Cell Culture Process and performs the necessary steps to synthesize Factor VIII protein. This process might include the introduction of specific stimuli or chemicals to induce Factor VIII production.

- Harvesting Process: Extracts the Factor VIII protein from the cell culture media. This process involves techniques like centrifugation and filtration to separate the protein from the cells and other components.

- Purification Process: Refines the harvested Factor VIII, removing impurities and concentrating the protein. This involves various chromatographic techniques, such as affinity chromatography, to isolate and purify the desired protein.

- Formulation and Filling Process: Formulates the purified Factor VIII into a stable, injectable form and fills vials or syringes. This step ensures the final product is ready for distribution.

- Quality Control Process: Monitors the entire production process, testing the Factor VIII at various stages to ensure its safety, purity, and potency. This includes tests for contaminants, activity levels, and stability.

Interaction Between Processes in the Model

The processes in the Factor VIII production model must interact to coordinate their activities and pass data between stages. Communication and synchronization are critical for the smooth functioning of the model. Consider the following example illustrating the interaction between the Cell Culture Process and the Production Process:

Cell Culture Process:

1. Grow cells in bioreactor.

2. Monitor cell density and nutrient levels.

3.Once cell density reaches a certain threshold, send a “ReadyForProduction” message to the Production Process.

Production Process:

1. Waits to receive a “ReadyForProduction” message from the Cell Culture Process.

2. Upon receiving the message, retrieve the cell culture media from the Cell Culture Process.3. Introduce stimuli to induce Factor VIII production.

4. Monitor Factor VIII production levels.

5.Once Factor VIII production reaches a specific level, send a “ProductionComplete” message to the Harvesting Process.

In this scenario, the “ReadyForProduction” and “ProductionComplete” messages act as synchronization points, ensuring that the Production Process starts only when the Cell Culture Process is ready and that the Harvesting Process begins only after the production is complete. This structured communication and synchronization are essential for coordinating the concurrent execution of the processes.

Concurrency Strategies for Factor VIII Processing

In the realm of Factor VIII production, efficiently managing concurrent operations is paramount to maximizing throughput and minimizing processing time. Several concurrency strategies can be employed to achieve this, each with its own set of advantages and disadvantages. The choice of strategy significantly impacts the overall performance and scalability of the production process.

Concurrency Strategies for Factor VIII Production

Several concurrency strategies are applicable to Factor VIII production, allowing for parallel execution of different stages. These strategies are critical for optimizing the utilization of resources and reducing overall processing time.

- Pipeline Processing: This strategy involves breaking down the Factor VIII production process into a series of sequential stages, each handled concurrently by a different worker or process. For instance, one worker could be responsible for cell culture, another for harvesting, a third for purification, and a fourth for formulation. As each stage completes its task on a batch of Factor VIII, the batch is passed to the next stage in the pipeline.

This allows for continuous processing and can significantly reduce the overall time required to produce a batch. The effectiveness of pipeline processing depends on the balanced execution time of each stage; if one stage becomes a bottleneck, the entire pipeline’s efficiency suffers.

- Data Parallelism: Data parallelism involves dividing the input data (e.g., a large batch of cell culture) into smaller subsets and processing each subset concurrently. For Factor VIII production, this could mean running multiple bioreactors simultaneously, each producing a portion of the final product. The results from each bioreactor are then combined later in the process. This strategy is particularly effective when the processing steps are independent and can be applied to each subset of data without dependencies.

- Task Parallelism: Task parallelism involves breaking down the overall process into independent tasks that can be executed concurrently. This might involve running multiple purification steps in parallel or performing quality control tests on different samples simultaneously. This strategy is suitable when the tasks are relatively independent and do not require frequent synchronization or data sharing.

- Hybrid Approaches: In practice, a combination of these strategies is often used. For example, a pipeline approach might be implemented with data parallelism within a specific stage. This allows for the maximum utilization of available resources and optimization of the overall process. The specific combination will depend on the characteristics of the production process and the available hardware.

Thread-Based vs. Process-Based Concurrency

Both thread-based and process-based concurrency can be used to implement the strategies mentioned above. The choice between them depends on factors like the underlying operating system, the complexity of the tasks, and the need for resource isolation.

- Thread-Based Concurrency: Threads are lightweight execution units within a single process. They share the same memory space, which allows for fast communication and data sharing. However, this shared memory also introduces the potential for race conditions and the need for synchronization mechanisms (e.g., mutexes, semaphores) to protect shared data.

- Process-Based Concurrency: Processes are independent execution units, each with its own memory space. This provides strong isolation and prevents data corruption. Communication between processes typically involves inter-process communication (IPC) mechanisms, such as pipes, message queues, or shared memory, which are generally slower than thread-based communication.

Pros and Cons of Thread-Based Concurrency

Thread-based concurrency offers advantages in terms of resource utilization and communication speed, but it also presents challenges related to data synchronization and debugging.

- Pros:

- Lower Overhead: Creating and managing threads is typically less resource-intensive than creating and managing processes.

- Shared Memory: Threads share the same memory space, allowing for efficient communication and data sharing. This reduces the overhead associated with transferring data between execution units.

- Faster Context Switching: Switching between threads within the same process is generally faster than switching between processes.

- Cons:

- Data Synchronization Complexity: Managing shared memory requires careful synchronization to prevent race conditions and data corruption. This can lead to complex and error-prone code.

- Debugging Challenges: Debugging multithreaded applications can be more challenging than debugging single-threaded applications, due to the non-deterministic nature of thread execution.

- Global Interpreter Lock (GIL) Limitations (in some languages): In languages like Python, the GIL can limit the true parallelism of threads, as only one thread can hold control of the Python interpreter at any given time. This can limit the performance benefits of threading, particularly for CPU-bound tasks.

Pros and Cons of Process-Based Concurrency

Process-based concurrency provides robust isolation and simplifies data management, but it can introduce overhead related to process creation and inter-process communication.

- Pros:

- Strong Isolation: Processes have their own memory space, which prevents data corruption and simplifies debugging. If one process crashes, it does not affect other processes.

- Simplified Synchronization: Because processes do not share memory by default, synchronization issues are less likely to occur.

- True Parallelism: Processes can utilize multiple CPU cores without being constrained by a GIL.

- Cons:

- Higher Overhead: Creating and managing processes is generally more resource-intensive than creating and managing threads.

- Inter-Process Communication (IPC): Communication between processes typically involves IPC mechanisms, which can be slower than thread-based communication.

- Increased Memory Usage: Each process has its own memory space, which can lead to higher overall memory consumption.

Resource Management in a Concurrent Factor VIII System

Effective resource management is paramount in a concurrent Factor VIII production system. The simultaneous operation of multiple processes necessitates careful allocation and monitoring of critical resources to maximize efficiency, prevent bottlenecks, and ensure product quality. This section explores the vital resources involved and strategies for their efficient management.

Critical Resources in Factor VIII Production

Several resources are critical in Factor VIII production, each playing a vital role in the overall process. Efficient management of these resources is essential to avoid delays and maintain consistent output.

- Bioreactors: These are the primary vessels where cell cultures producing Factor VIII are grown. Their availability and capacity are directly proportional to production output.

- Purification Columns: These columns, employing various chromatographic techniques, are crucial for separating and purifying Factor VIII from the cell culture media. The number, size, and efficiency of these columns significantly impact processing time.

- Filtration Systems: Filtration systems, including depth filters and ultrafiltration units, are essential for removing impurities and concentrating the Factor VIII product. The throughput of these systems directly affects the overall processing speed.

- Buffer Preparation and Storage: The availability and quality of buffers are critical for maintaining optimal conditions throughout the purification process. Insufficient or improperly prepared buffers can lead to product degradation or process failure.

- Personnel and Expertise: Skilled technicians and process engineers are essential for operating and maintaining the equipment, monitoring the process, and troubleshooting any issues. Staff availability directly impacts operational efficiency.

- Cleanroom Space: Maintaining a sterile environment is crucial for preventing contamination. Adequate cleanroom space for various stages of production is essential.

- Utilities: Reliable access to utilities such as electricity, water, and compressed air is fundamental for all production steps. Any interruption can cause significant downtime.

Resource Management in a Concurrent System

Managing resources in a concurrent Factor VIII production system requires a strategic approach to ensure efficient allocation and prevent conflicts. The goal is to maximize resource utilization while maintaining process integrity.

- Scheduling and Prioritization: Implementing a robust scheduling system is essential. This involves prioritizing tasks based on deadlines, resource availability, and batch size. Software tools can be employed to optimize scheduling and provide real-time updates. For example, a batch nearing its final purification stage might be prioritized over a newly initiated cell culture.

- Resource Pooling: This involves creating a central pool of resources, such as bioreactors or purification columns, that can be dynamically allocated to different concurrent processes as needed. This approach maximizes utilization and reduces idle time.

- Capacity Planning: Accurately forecasting future demand and planning for sufficient resource capacity is crucial. This involves analyzing historical production data, predicting future needs, and scaling resources accordingly. For example, if demand is projected to increase by 20% over the next year, additional bioreactors or purification columns may need to be acquired.

- Real-time Monitoring and Control: Implementing a system for real-time monitoring of resource utilization is critical. This includes monitoring bioreactor occupancy, purification column usage, and buffer inventory levels. Automated alerts can be set up to notify personnel of any deviations from the planned schedule or resource shortages.

- Standard Operating Procedures (SOPs): Developing and strictly adhering to SOPs for all processes ensures consistency and reduces the risk of errors. SOPs should clearly define resource allocation protocols, cleaning and maintenance schedules, and troubleshooting procedures.

Preventing Resource Contention and Deadlocks

Resource contention and deadlocks can severely impact the efficiency and reliability of a concurrent Factor VIII production system. Implementing preventative measures is essential.

- Locking Mechanisms: Employing locking mechanisms is essential for controlling access to shared resources. For example, a purification column could be locked by a specific process until it’s released, preventing another process from interfering.

- Timeouts: Setting time limits on resource requests helps prevent indefinite blocking and potential deadlocks. If a process cannot acquire a resource within a specified time, it should release its current resources and retry later or alert an operator.

- Resource Ordering: Establishing a predefined order for resource acquisition can help prevent deadlocks. For example, if two processes require access to both a bioreactor and a purification column, they should always request the bioreactor first and then the column.

- Deadlock Detection and Resolution: Implementing a system for detecting and resolving deadlocks is crucial. This might involve monitoring resource allocation patterns and identifying circular dependencies that indicate a deadlock. Resolution strategies could include preemption (forcing a process to release a resource) or rollback (reverting a process to a previous state).

- Resource Allocation Algorithms: Utilizing sophisticated resource allocation algorithms can optimize resource utilization and minimize contention. Algorithms such as round-robin or priority-based scheduling can be employed to distribute resources fairly and efficiently.

Designing a Scalable Factor VIII Production Workflow

To achieve scalable Factor VIII production, a well-defined workflow that leverages the process model for concurrency is essential. This involves breaking down the complex manufacturing process into a series of independent, concurrent processes that can be executed simultaneously. This approach minimizes bottlenecks, optimizes resource utilization, and ultimately increases production capacity. The following Artikels the key considerations for designing such a workflow.

Workflow Organization into Concurrent Processes

The Factor VIII production process can be effectively organized into distinct, concurrent processes to improve efficiency and scalability. Each process should be designed to operate independently, with well-defined inputs, outputs, and dependencies. This allows for parallel execution, reducing the overall processing time and increasing throughput. Coordination and communication between processes are crucial, but the goal is to minimize interdependencies to maximize concurrency.

Process Steps and Dependencies Table

The following table illustrates the process steps involved in Factor VIII production, along with their dependencies. The table is designed to be responsive, adapting to different screen sizes for optimal viewing.

| Process Step | Description | Dependencies | Concurrent Processes |

|---|---|---|---|

| Cell Culture Initiation | Initiation of cell cultures for Factor VIII production. This involves thawing and expanding cell banks. | None | Process A |

| Cell Culture Expansion | Expansion of cell cultures to the required volume for Factor VIII production. | Cell Culture Initiation | Process A |

| Factor VIII Production (Fermentation) | The process of culturing cells to produce Factor VIII protein. This occurs in bioreactors. | Cell Culture Expansion, Media Preparation | Process B |

| Media Preparation | Preparation of the cell culture media, including sterile filtration and quality control. | None | Process C |

| Harvesting | Separation of Factor VIII from the cell culture media. | Factor VIII Production (Fermentation) | Process D |

| Purification | Purification of Factor VIII using chromatographic techniques. | Harvesting | Process E |

| Formulation | Formulation of the purified Factor VIII into the final product. | Purification | Process F |

| Filling and Lyophilization | Filling vials with the formulated product and lyophilization (freeze-drying) to stabilize it. | Formulation | Process G |

| Quality Control and Testing | Quality control testing of the final product. | Filling and Lyophilization | Process H |

| Packaging and Storage | Packaging of the final product and storage under appropriate conditions. | Quality Control and Testing | Process I |

This table illustrates how different steps can be performed concurrently. For example, while cell culture expansion is underway, media preparation can proceed independently. Similarly, harvesting can start once fermentation is complete, and so on. The “Concurrent Processes” column indicates how various processes can run simultaneously, thereby reducing the overall production timeline. This modular approach is key to achieving scalability in Factor VIII production.

Implementing Inter-Process Communication (IPC)

In a concurrent Factor VIII production system, processes need to exchange information to coordinate their activities, share data, and synchronize their operations. This exchange is facilitated through Inter-Process Communication (IPC) mechanisms, which are critical for the efficient and reliable operation of the system. Without effective IPC, processes would operate in isolation, severely limiting the benefits of concurrency and scalability.

The Importance of Inter-Process Communication (IPC)

IPC is the cornerstone of a well-functioning concurrent system. It allows independent processes to communicate and collaborate, enabling the system to achieve its overall objectives.IPC is essential for several key reasons:

- Data Sharing: Processes can share intermediate results, raw materials data, or final product specifications. This shared data is crucial for processes that rely on each other.

- Coordination and Synchronization: Processes can signal events, request resources, or coordinate the execution of tasks. This is vital for managing dependencies and preventing conflicts. For example, a process might signal another when a batch of Factor VIII is ready for the next purification step.

- Error Handling and Recovery: Processes can report errors or failures to other processes, which can then take corrective action. This improves the system’s overall resilience. For instance, if a process responsible for a specific step detects an anomaly, it can notify other processes involved in the workflow.

- Load Balancing: IPC can be used to distribute workloads across multiple processes, optimizing resource utilization and improving throughput. This is particularly important in a Factor VIII production environment where demand can fluctuate.

Examples of IPC Mechanisms for Factor VIII Production

Various IPC mechanisms can be employed in a Factor VIII production system, each with its strengths and weaknesses. The choice of mechanism depends on factors such as the complexity of the communication, the volume of data exchanged, and the required performance.Here are some common IPC mechanisms that can be utilized:

- Shared Memory: Multiple processes can access and modify a shared region of memory. This is often the fastest IPC method, suitable for high-volume data exchange. However, it requires careful synchronization to avoid data corruption due to concurrent access. Imagine several processes that need to access the same data on the quality of the Factor VIII, such as purity or concentration.

The data is stored in a shared memory region.

- Message Queues: Processes send messages to a queue, and other processes retrieve them. This is an asynchronous method, which can improve the system’s responsiveness. Message queues provide a buffer, allowing processes to operate at different speeds. This is useful in cases where a process generates data faster than another process can consume it.

- Sockets: Sockets allow processes to communicate over a network. This is suitable for distributed systems where processes may reside on different machines. Sockets provide a flexible and standard way to exchange data, regardless of the underlying network infrastructure. For example, a process on a different machine might analyze the production process in real-time.

- Pipes: Pipes provide a unidirectional communication channel between two processes. One process writes data to the pipe, and the other process reads from it. Pipes are simple and efficient for passing small amounts of data. This is often used in situations where a process’s output becomes the input of another process, like in a pipeline of purification steps.

- Files: Processes can exchange data by writing to and reading from files. This is a simple, persistent method, but it can be slower than other methods. Files are useful for logging or for persisting data for later analysis.

Designing a Simple IPC Protocol for Exchanging Data

Designing a simple IPC protocol involves defining the format of the messages exchanged between processes. The protocol should be clear, concise, and robust enough to handle potential errors. The protocol should also consider the types of data being exchanged and the frequency of communication.A simple protocol for exchanging Factor VIII batch information could look like this:

The message structure could be as follows:

| Field | Data Type | Description |

|---|---|---|

| Message Type | Integer | Indicates the type of message (e.g., “Batch Start”, “Data Update”, “Error Report”). |

| Batch ID | Integer | Unique identifier for the Factor VIII batch. |

| Timestamp | Timestamp | Timestamp of the message creation. |

| Data Payload | String/Binary | Contains the specific data relevant to the message type. |

The following message types could be used:

- Batch Start: Sent by the batch initiation process to signal the start of a new batch. The payload could contain initial batch parameters.

- Data Update: Sent by a process to provide updates on batch progress. The payload could include measurements, or process status.

- Error Report: Sent by a process to report errors. The payload would include error codes and diagnostic information.

An example of a ‘Data Update’ message in JSON format:

“message_type”: 2, “batch_id”: 12345, “timestamp”: “2024-01-26T10:00:00Z”, “data_payload”: “‘purity’: 98.5, ‘concentration’: 2.0”

This protocol can be implemented using any of the previously mentioned IPC mechanisms, such as message queues or sockets. The sender would format the data according to the protocol, and the receiver would parse the data and process it accordingly. The key is to have a standardized format that all processes can understand. This ensures that processes can reliably exchange data and work together efficiently in the Factor VIII production workflow.

Monitoring and Debugging a Concurrent Factor VIII System

Monitoring and debugging are crucial for maintaining the performance, stability, and reliability of a concurrent Factor VIII production system. Effective monitoring allows for proactive identification of bottlenecks, resource contention, and potential failures, while debugging tools and techniques help in quickly diagnosing and resolving issues that arise in the complex, concurrent environment. This section will delve into methods for monitoring performance, strategies for debugging, and examples of tools and techniques for tackling concurrency-related problems.

Methods for Monitoring Performance

To effectively monitor a concurrent Factor VIII production system, a multifaceted approach is necessary. This involves tracking key performance indicators (KPIs), utilizing system-level monitoring tools, and implementing application-specific metrics. The following details these approaches:

- Key Performance Indicators (KPIs): Establishing and tracking relevant KPIs is fundamental. These metrics provide insights into the overall health and efficiency of the system. Examples include:

- Throughput: Measuring the rate at which Factor VIII product is being processed (e.g., liters per hour, batches per day).

- Latency: Tracking the time it takes for a specific task to complete (e.g., the time required for a purification step).

- Resource Utilization: Monitoring the utilization of CPU, memory, disk I/O, and network bandwidth. High resource utilization can indicate bottlenecks.

- Queue Lengths: Observing the number of tasks waiting to be processed in various queues (e.g., tasks waiting for a specific resource or process). Excessively long queue lengths can signal a problem.

- Error Rates: Tracking the frequency of errors and failures in different parts of the system.

- System-Level Monitoring Tools: Leveraging system-level tools provides a comprehensive view of the underlying infrastructure. Tools such as `top`, `htop`, `vmstat`, and `iostat` on Linux-based systems, or Performance Monitor on Windows, are invaluable. These tools provide real-time data on:

- CPU usage per process: Identify processes that are consuming a disproportionate amount of CPU time.

- Memory usage: Detect memory leaks or processes that are excessively consuming memory.

- Disk I/O: Pinpoint disk bottlenecks that may be impacting performance.

- Network traffic: Monitor network bandwidth utilization to identify potential communication problems.

- Application-Specific Metrics: Implement custom metrics within the Factor VIII production application to gain insights into specific processes and workflows. This often involves logging data at critical points in the code, using instrumentation libraries, or integrating with a dedicated monitoring platform. This allows for:

- Tracking the duration of specific operations: Measure the time taken for individual steps in the production process.

- Monitoring the state of concurrent processes: Track the status of different processes (e.g., running, waiting, blocked).

- Collecting data on resource allocation: Monitor how resources are being allocated to different processes.

- Log Aggregation and Analysis: Centralized logging is essential for correlating events across different processes and systems. Use a log aggregation tool (e.g., ELK Stack – Elasticsearch, Logstash, Kibana; or Splunk) to collect, store, and analyze logs from all components of the system. This facilitates:

- Identifying patterns and anomalies: Analyze log data to identify trends and unusual events.

- Correlating events across multiple processes: Track events that span multiple processes to understand the flow of operations.

- Troubleshooting errors and failures: Use log data to pinpoint the root causes of problems.

Strategies for Debugging Issues in a Concurrent Environment

Debugging a concurrent Factor VIII production system presents unique challenges, as issues may be non-deterministic and difficult to reproduce. Employing the right strategies is crucial for effectively identifying and resolving problems. These strategies include:

- Reproducing the Problem: Attempting to reproduce the issue is a critical first step. This may involve:

- Simulating the production environment: Recreating the production environment as closely as possible on a testing system.

- Using controlled inputs: Using the same input data and configurations that led to the problem.

- Increasing logging verbosity: Adding more logging statements to the code to capture more detailed information about the execution flow.

- Isolating the Problem: Once the problem is reproducible, the next step is to isolate it. This may involve:

- Dividing and conquering: Breaking down the system into smaller components and testing each component individually.

- Commenting out code: Temporarily disabling parts of the code to see if the problem disappears.

- Using breakpoints: Setting breakpoints in the code to pause execution and inspect the state of the program at various points.

- Understanding Concurrency Issues: Concurrency-related problems often manifest as:

- Race conditions: Occur when the outcome of a program depends on the order in which concurrent threads or processes execute.

- Deadlocks: Occur when two or more processes are blocked indefinitely, waiting for each other to release resources.

- Livelocks: Occur when processes repeatedly attempt to perform an action but are unsuccessful due to contention.

- Starvation: Occurs when a process is repeatedly denied access to a resource, even though it is available.

- Using Debugging Tools: Leverage specialized debugging tools to gain insights into the execution of concurrent processes.

- Debuggers with concurrency support: Use debuggers (e.g., GDB, Visual Studio Debugger) that can handle multiple threads or processes.

- Thread and process monitoring tools: Use tools that visualize the state of threads and processes, such as thread profilers.

- Memory analysis tools: Use memory analysis tools to detect memory leaks, incorrect memory access, and other memory-related problems.

- Analyzing Thread Dumps and Process Dumps: When a system is experiencing issues, capturing thread dumps and process dumps can provide valuable information.

- Thread dumps: Capture the state of all threads in a process, including their call stacks. This can help identify deadlocks, blocked threads, and other concurrency problems.

- Process dumps: Capture the state of a process, including its memory and resources. This can help identify memory leaks and other resource-related problems.

Tools and Techniques for Resolving Concurrency-Related Problems

Several tools and techniques can be used to identify and resolve concurrency-related problems in a Factor VIII production system. The choice of tools and techniques depends on the specific nature of the problem.

- Code Review and Static Analysis: Conduct thorough code reviews and use static analysis tools to identify potential concurrency issues before they reach production. These tools can:

- Detect potential race conditions: Identify code sections where multiple threads or processes may be accessing shared resources without proper synchronization.

- Identify deadlocks: Detect potential deadlock scenarios based on the use of locks and mutexes.

- Check for thread safety violations: Ensure that code is thread-safe by analyzing the use of shared data structures and resources.

- Locking and Synchronization Primitives: Employ appropriate locking and synchronization primitives to protect shared resources from concurrent access. This includes:

- Mutexes (Mutual Exclusion Locks): Ensure that only one thread or process can access a critical section of code at a time.

- Semaphores: Control access to a limited number of resources.

- Read-Write Locks: Allow multiple threads to read a resource concurrently, but only allow one thread to write to it at a time.

- Atomic Operations: Perform operations on shared variables in a single, indivisible step.

- Testing and Simulation: Utilize testing and simulation techniques to uncover concurrency issues.

- Unit Testing: Write unit tests that specifically target concurrent code, simulating multiple threads or processes.

- Integration Testing: Test the interaction between different components of the system in a concurrent environment.

- Load Testing: Simulate high loads to stress-test the system and identify concurrency bottlenecks.

- Fuzz Testing: Use fuzzing techniques to generate random inputs to the system to uncover unexpected behavior and concurrency-related issues.

- Tools for Detecting Deadlocks and Race Conditions: Specialized tools can assist in the detection of specific concurrency problems.

- Deadlock detectors: Tools that analyze the state of the system and identify potential deadlocks. These tools can be integrated into the debugging process or run as part of the build process.

- Race condition detectors: Tools that analyze the code and identify potential race conditions. These tools often use techniques like dynamic analysis or static analysis to identify these problems.

- Resource Profiling: Use resource profiling tools to monitor resource usage and identify bottlenecks.

- CPU Profilers: Identify the functions or code sections that are consuming the most CPU time.

- Memory Profilers: Detect memory leaks and identify memory usage patterns.

- I/O Profilers: Identify disk I/O bottlenecks.

- Example: A Real-World Scenario – The “Lost Update” Problem: Consider a scenario in Factor VIII production where two processes attempt to update the same batch record simultaneously. Without proper synchronization, one process might overwrite the changes made by the other, leading to data loss. This is known as the “lost update” problem. Implementing a transaction with appropriate locking mechanisms, such as optimistic locking (e.g., using a version number) or pessimistic locking (e.g., exclusive lock on the record) can prevent this issue.

If the version number changes between the read and write operations, the update is rejected, and the process must re-read the data and re-apply its changes. This approach ensures data integrity in a concurrent environment.

Optimizing Performance and Scalability

Optimizing the performance and scalability of a concurrent Factor VIII production system is critical for meeting increasing demand and maintaining operational efficiency. This involves a multi-faceted approach, focusing on fine-tuning individual processes, optimizing resource utilization, and designing the system to handle larger workloads. The following sections delve into specific techniques and strategies to achieve these goals.

Techniques for Optimizing Performance

Optimizing performance involves identifying and mitigating bottlenecks, streamlining processes, and maximizing the utilization of available resources. Several techniques can be employed to achieve this.

- Process Optimization: Analyze individual process steps to identify inefficiencies. This includes reviewing incubation times, purification methods, and formulation processes. Optimize these steps to reduce processing time without compromising product quality. For example, using more efficient chromatography columns can significantly reduce purification time.

- Code Profiling and Optimization: Utilize code profiling tools to identify performance bottlenecks within the software that manages the concurrent processes. These tools can pinpoint slow-running functions or areas where resources are being inefficiently used. Once identified, optimize the code by refactoring, using more efficient algorithms, and minimizing unnecessary operations.

- Resource Allocation and Scheduling: Implement a robust resource allocation and scheduling system to ensure that processes have access to the necessary resources (e.g., bioreactors, purification equipment, storage) when needed. This includes strategies such as:

- Prioritization: Assign priorities to different processes to ensure that critical steps are completed promptly.

- Dynamic Resource Allocation: Implement a system that can dynamically allocate resources based on real-time demand.

- Caching and Data Optimization: Implement caching mechanisms to store frequently accessed data, reducing the need to repeatedly retrieve information from slower storage systems. Optimize data structures and database queries to improve data access speed.

- Asynchronous Operations: Implement asynchronous operations where possible. Instead of waiting for a process to complete before starting the next one, the system can initiate a process and continue with other tasks. This improves overall throughput.

- Load Balancing: Distribute the workload across multiple processing units (e.g., servers, threads) to prevent any single unit from becoming a bottleneck. Load balancing ensures that the processing load is evenly distributed, enhancing overall performance.

Methods for Scaling the System

Scaling a concurrent Factor VIII production system involves increasing its capacity to handle larger production volumes. Several methods can be employed to achieve this.

- Horizontal Scaling: Add more processing units (e.g., bioreactors, purification skids, servers) to the system. This is a common and effective way to increase capacity. As demand grows, additional units can be added to the system, enabling it to handle larger production volumes. For example, adding more bioreactors allows for a higher batch size.

- Vertical Scaling: Increase the capacity of existing processing units. This might involve upgrading equipment to handle larger volumes, faster processing speeds, or improved efficiency. For example, upgrading to a bioreactor with a higher capacity or faster mixing capabilities.

- Process Parallelization: Break down complex processes into smaller, independent tasks that can be executed concurrently. This leverages the power of multi-core processors and distributed systems.

- Automation: Automate manual processes to reduce human intervention and improve efficiency. Automation can significantly reduce the time required for various steps, such as media preparation, sample handling, and data analysis.

- Optimized Workflow Design: Redesign the production workflow to eliminate bottlenecks and improve the flow of materials and information. This involves analyzing the entire production process, identifying areas for improvement, and implementing changes to streamline the workflow.

- Use of Cloud Services: Leverage cloud-based services for resource management, data storage, and processing. Cloud services provide scalability and flexibility, allowing the system to dynamically adjust its resources based on demand.

Visual Representation of Scaling

The following provides a descriptive overview of how scaling can be achieved in a Factor VIII production system. It does not contain any images, but explains the concept of scaling.

Initial State:

The system starts with a defined production capacity, consisting of a set of bioreactors, purification units, and supporting infrastructure. The system is operating at a certain throughput, producing a specific amount of Factor VIII per month.

Scaling Strategy: Horizontal Scaling

To scale horizontally, the system adds more bioreactors and associated purification units. For example, adding 2 more bioreactors to an existing system of 4 would increase the production capacity by 50% (assuming each bioreactor has similar capacity). The system would then be able to process more batches concurrently, leading to an increase in the total Factor VIII produced per month.

Scaling Strategy: Vertical Scaling

To scale vertically, the system can upgrade the existing bioreactors to larger capacity models. For example, replacing existing 2,000-liter bioreactors with 4,000-liter bioreactors would effectively double the production capacity per batch, without adding more units. The same can be done for purification units, such as upgrading chromatography columns to handle larger volumes.

Combined Approach:

The most effective scaling strategy often involves a combination of horizontal and vertical scaling. This means adding more units (horizontal) and upgrading existing units (vertical) simultaneously. For instance, adding a new bioreactor while upgrading the purification process to handle larger volumes will provide the best possible increase in capacity.

Outcome:

Through horizontal and vertical scaling, the system’s production capacity increases, allowing it to meet growing demand for Factor VIII. The scalability allows the system to adapt to changes in demand, ensuring a reliable supply of this critical medication.

Real-World Examples and Case Studies

Understanding the application of the process model for concurrency in biotechnology, particularly in Factor VIII production, requires examining real-world examples and case studies. These examples provide valuable insights into the practical challenges, lessons learned, and measurable outcomes achieved through the implementation of concurrent processing strategies. By analyzing these case studies, we can better appreciate the impact of concurrency on efficiency, scalability, and overall production success.

Biogen’s Recombinant Factor VIII Production

Biogen, a leading biotechnology company, has experience in the production of recombinant Factor VIII (rFVIII) for treating hemophilia. While specific details of their process model implementation are proprietary, their success in large-scale rFVIII production offers relevant insights.

- Scale-Up Strategies: Biogen has likely employed various scale-up strategies, including:

- Increasing bioreactor volume while maintaining optimized process parameters.

- Implementing multiple bioreactors operating in parallel to increase overall production capacity.

- Optimizing downstream processing steps, such as chromatography and filtration, to handle increased product volumes.

- Concurrency in Action: The process model, if implemented, would involve concurrent execution of different stages:

- Multiple bioreactors operating simultaneously, each producing rFVIII.

- Parallel processing of batches in downstream purification steps.

- Concurrent quality control testing to ensure product release.

- Challenges Faced:

- Maintaining Consistency: Ensuring consistent product quality across multiple batches and bioreactors is a significant challenge. This requires rigorous process control and monitoring.

- Process Optimization: Optimizing each step of the process to maximize yield and minimize waste is an ongoing effort.

- Regulatory Compliance: Meeting stringent regulatory requirements for rFVIII production necessitates meticulous documentation and adherence to Good Manufacturing Practices (GMP).

- Lessons Learned:

- Process Validation is Critical: Thorough process validation is essential to demonstrate that the production process consistently yields a product that meets quality attributes.

- Data Analysis is Key: Comprehensive data analysis helps identify bottlenecks, optimize process parameters, and improve overall efficiency.

- Collaboration is Important: Collaboration between different departments, such as upstream processing, downstream processing, and quality control, is vital for successful rFVIII production.

- Measurable Outcomes: While specific data is often confidential, Biogen’s success in producing large quantities of rFVIII indicates positive outcomes:

- Increased production capacity to meet the growing demand for rFVIII.

- Improved product yield and efficiency.

- Enhanced process robustness and reliability.

Case Study: Parallel Processing in a Hypothetical Factor VIII Manufacturing Facility

Consider a hypothetical Factor VIII manufacturing facility aiming to increase production output by 50%. They implement a process model focused on concurrency.

- Current State: The facility currently uses a batch process with a single bioreactor and sequential downstream processing steps.

- Proposed Solution: They introduce parallel processing by:

- Adding a second bioreactor to operate in parallel with the existing one.

- Duplicating key downstream processing units, such as chromatography columns and filtration systems.

- Implementing a distributed control system (DCS) to manage the concurrent operations.

- Implementation:

- The facility needs to design the system, including the physical layout of the equipment and the control system architecture.

- The facility must establish standard operating procedures (SOPs) for the concurrent operations.

- The facility must train personnel on the new processes and equipment.

- Outcomes:

- Production Capacity Increase: The facility achieves a 45% increase in Factor VIII production, close to the target.

- Cycle Time Reduction: The overall production cycle time is reduced by 20% due to parallel processing.

- Cost Optimization: Although there are initial capital expenditures for new equipment, the facility sees a decrease in cost per unit of Factor VIII produced due to improved efficiency.

- Improved Scalability: The modular design allows for further expansion by adding more bioreactors and downstream processing units as needed.

- Challenges and Lessons Learned:

- Process Validation: Thorough process validation is required to ensure that the product quality remains consistent.

- Equipment Reliability: Redundancy in key equipment is essential to mitigate downtime.

- Personnel Training: Adequate training is crucial to ensure that operators can effectively manage the concurrent operations.

Example: Utilizing Multiple Bioreactors

Implementing multiple bioreactors working in parallel represents a concrete application of the process model for concurrency. This allows for a significant increase in overall production capacity. The image below illustrates this concept.

Illustration of Multiple Bioreactors in Parallel. The illustration depicts two or more bioreactors, represented as cylindrical vessels with various inlets, outlets, and internal components. These bioreactors are connected to common upstream and downstream processing units, such as feed tanks, pumps, and purification systems. The bioreactors operate simultaneously, each producing Factor VIII independently, which increases overall production capacity. Control systems and monitoring devices are in place to ensure that all bioreactors maintain optimal conditions for cell growth and Factor VIII production.

- Benefits:

- Increased throughput: Multiple bioreactors can process larger volumes of culture medium simultaneously, leading to a higher total yield of Factor VIII.

- Improved flexibility: If one bioreactor experiences a problem, the others can continue to operate, maintaining production.

- Reduced cycle time: The overall production cycle time can be reduced, leading to faster delivery of the final product.

- Challenges:

- Maintaining consistency: Ensuring that all bioreactors produce Factor VIII with the same quality attributes requires careful control of process parameters.

- Increased complexity: Managing multiple bioreactors and associated equipment adds complexity to the production process.

- Higher initial investment: The cost of purchasing and installing multiple bioreactors can be substantial.

- Implementation Considerations:

- Process Optimization: Thorough optimization of the bioreactor operating parameters, such as temperature, pH, and dissolved oxygen, is essential.

- Control Systems: Advanced control systems are needed to monitor and regulate the bioreactors.

- Scale-Up Strategy: The design must consider the overall scale-up strategy, including downstream processing and quality control.

Wrap-Up

In conclusion, the application of the process model for concurrency offers a powerful approach to scaling out Factor VIII production. By embracing concurrent strategies, careful resource management, and robust monitoring, manufacturers can overcome production bottlenecks and significantly increase their capacity. This methodology provides a blueprint for achieving optimal performance and scalability in the dynamic landscape of biotechnology, ensuring that production can meet the needs of patients and healthcare providers.

This knowledge will enable you to be able to apply it to your project.

FAQ Overview

What is the primary advantage of using a process model for concurrency in Factor VIII production?

The primary advantage is improved resource utilization, enabling more efficient processing and minimizing idle time for equipment and personnel.

How does concurrency help address bottlenecks in Factor VIII manufacturing?

Concurrency allows multiple tasks to run simultaneously, thereby bypassing the sequential limitations of traditional workflows and expediting processes.

What are the key considerations when choosing between thread-based and process-based concurrency?

Considerations include the overhead of creating and managing threads/processes, the complexity of inter-process communication, and the degree of isolation needed for different tasks.

What are the potential challenges of implementing a concurrent Factor VIII production system?

Challenges include the complexity of debugging, managing resources, and preventing deadlocks or race conditions.